In this vast landscape of product development, choosing the right sensors is the base of laying a strong foundation. It is not merely about picking sensors, it’s about the intricacies of your product’s needs and finding the perfect match between function and form.

Making the world smarter, one sensor-enabled device at a time.

Imagine you are building a smart home device. Your journey starts with a simple question: what problem does your device aim to solve for homeowners? Is it about optimizing energy usage or enhancing convenience? With this clarity in mind, you delve into the realm of sensor selection.

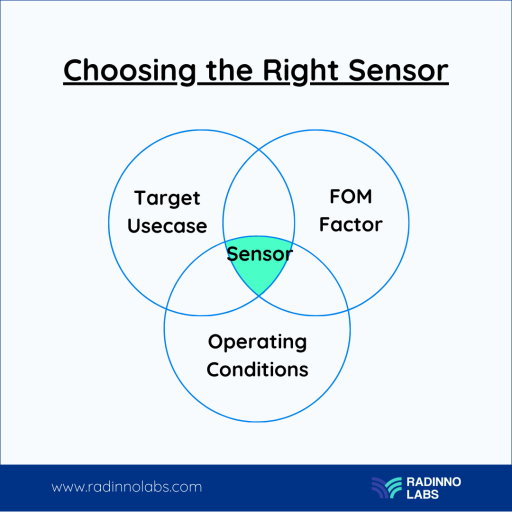

Let us look closer into the journey of selecting the right sensor for your products.

Start with the Problem not the Product – This advice stands true at all levels 🦉

Sensors are available in numerous shapes, sizes and ranges. You need to have a good understanding of the problem your product is going to solve to pick the right sensor for your product.

Sensors measure/detect a certain PHYSICAL PARAMETER. Let’s label this as PHYTER.

Sensors as a component have a defined set of characteristics on how it goes about measuring PHYTER. And here are the ones you should look at when picking one:

1. Range: The range of PHYTER values the sensor can measure.

For example thermal image sensors used in IR Cameras for industrial monitoring can measure temperatures in the RANGE from -20°C to 1900°C.

2. Accuracy: The precision with which a sensor can measure it’s PHYTER value.

A temperature can be designed to measure temperatures with a precision of 0.1°C/0.5°C/1°C. Say you are picking a sensor to measure the day’s weather 1°C accuracy should be sufficient – a user will mostly want to know whether the weather is 24°C or 25°C not precisely 24.3°C.

3. Latency: How quickly can the sensor measure changes in it’s PHYTER value? In other words the time taken to measure the current PHYTER. This is a parameter that can impact the performance of the system.

A typical example for low latency sensor would be the TORQUE sensors used in E-Bike Pedal Assists. Their latency greatly impacts the user’s driving experience and so they operate with a low latency of 5 to 10ms.

4. Operating Conditions: The environmental conditions under which the sensor can be used. This is expressed in terms of the temperature and humidity that the sensor body can withstand. A sensor’s performance and lifespan can be impacted by the environmental conditions it is exposed to during operation.

For instance, smartphones typically operate within temperatures ranging from 0°C to 35°C and exposing them to higher temperatures can affect battery life. On the other hand, industrial grade devices require sensors that can withstand much wider ranges such as -40°C to 85°C.

5. Storage Conditions: The environmental conditions under which the sensor will be stored and transported. Typically sensors are not powered or used in these scenarios so they can withstand a wider range of storage conditions than operating conditions. Also these are controlled environments and the conditions can be regulated as required.

The storage temperature of smartphones range from -20°C to 45°C

6. IP (Ingress Protection): Protection against dust and water.

Mostly this is achieved at a product level by potting/coating/sealing the electronics within the casing. If you are buying a sensor with a casing, then you must ensure it comes with the IP rating suitable for product you are building.

As an example Outdoor Security Cameras come with IP65 rating, which means they are Dust-tight i.e completely protected against dust and can withstand nominal water jets sprayed from any direction.

Overall, selecting and implementing a sensor involves considering multiple factors to ensure that the sensor can accurately and reliably measure the desired parameters.

One common mistake people do is go for a broad generic spec. This will increase the cost of the product unnecessarily without adding value to it’s usage. To build a cost optimized and quality product be specific on what you want and choose aptly.

In short success in product development hinges not on the gimmicks but on a deep understanding of real-world problems and a thoughtful selection of sensor technology to address them.

Just as every builder needs the right tools for their work, every product needs the right sensors to fully function and fulfill its purpose.

By carefully considering use cases, requirements, form factors, and operating conditions, we pave the way for solutions that resonate with users on a base level.